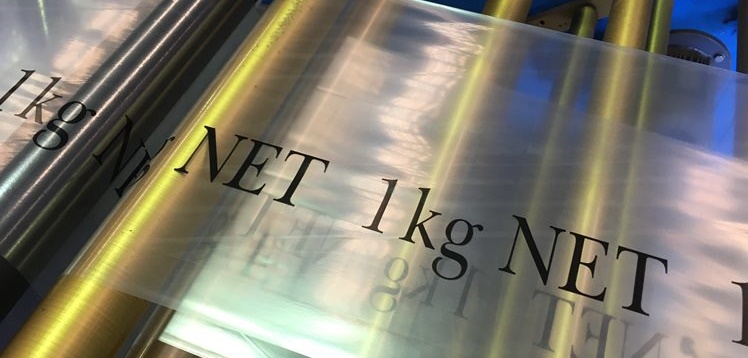

Printed Packaging

When it comes to quality printed packaging, Meridian is the name you can trust.

At Meridian, we are proud to have been manufacturing premium quality packaging solutions for Australian businesses for more than 35 years. From flexible packaging polyethylene products, film, poly tubes, bags, plastic packaging, printing and food grade plastic packaging for industrial use, we cater to all of your packaging needs.

Our in-house customisation processes allow us to create cost-effective solutions for branded packaging for a wide range of industries. Whether you’re looking for branded and labelled poly bags or promotional bunting, we guarantee a fast turnaround with professional and personalised service from concept to delivery.

At Meridian we are environmentally conscious and take care to ensure 100% of our plastic waste is recycled.

Printed

Poly Bags

Printed

Polytube

Australian

Made

All Waste

Recycled

Our Process

Manufactured locally in our Brisbane facility, our poly bags are versatile and suited to any purpose. When producing poly bags, we consider three main parameters: width, length and gauge (or thickness). We offer full customisation for poly bags including size, tint or colour, print, punch holes, handle punches and perforations. No matter your variables, we have the solution for your needs.

Our poly tube, which can be used to package individual products, is created through what is known as blown film extrusion. A poly tube is created firstly by blowing a bubble of plastic to its desired width. The gauge of the tube is then determined by the speed in which it passes through the nip rollers. For a thicker gauge, the rollers pull the poly tube very slowly to increase thickness, or for a thinner gauge, the rollers will pull the tube through at a faster pace, offering flexibility and choice for our clients.

At Meridian we do our utmost to reduce our carbon footprint. Our factory roof houses 190 individual solar panels, producing almost 60 kilowatts of electricity. On a sunny day, not only do we create enough energy to power our entire factory, but our solar panels feed excess electricity back into the grid.

Capabilities

1000+ Colours

Ultimate control with colours customisable to your business.

5 Colours Per Print

Pack a punch with custom packaging matching your brand.

Thickness

Ensure protection, without compromising product appearance.

Width

Create the perfect fit suited to your product and needs

Shrink Wrap

Tightly secure your products with our heat shrink technology.

Anti-static

Prevents static electricity build-up to protect your products.

Anti-block

Reduce friction between packaging to prevent sticking.

UV-stabilisation

Decrease risk of sun damage with UV resistant protection.

Frequently Asked Questions

What different colours can you produce?

Can you print on the plastic?

Is your plastic suitable for food packaging?

Can you recycle my unwanted plastic?

Is your plastic biodegradable?

Is your plastic recyclable?

Do you keep plastic bags and rolls of polytube in stock?

Do you have a price list or catalogue?

Do you make the product here in Australia?

What type of plastic products do you manufacture?

All of Meridian’s products are proudly made in Australia. We are Australian-owned and operated and therefore, can guarantee a fast and reliable turn-over.

Why Meridian?

With 35 years of industry experience, Meridian are the trusted experts when it comes to high quality and affordable custom packaging solutions. We are passionate about consistently delivering excellent service and high quality products at a fair and affordable price. As a local Australian business, we offer a fast turnaround so that our clients’ businesses can thrive.

Martin has spent the past three decades working exclusively in the plastics manufacturing industry and has dedicated his entire career to mastering the art of manufacturing quality plastic packaging products. Involved in every step of the process, Martin’s attention to detail alongside his passion, dedication and expertise prove to be an invaluable resource when it comes to customising packaging for your business.