Layflat Tubing

Continuous rolls of extruded film offer a practical and economical packaging solution.

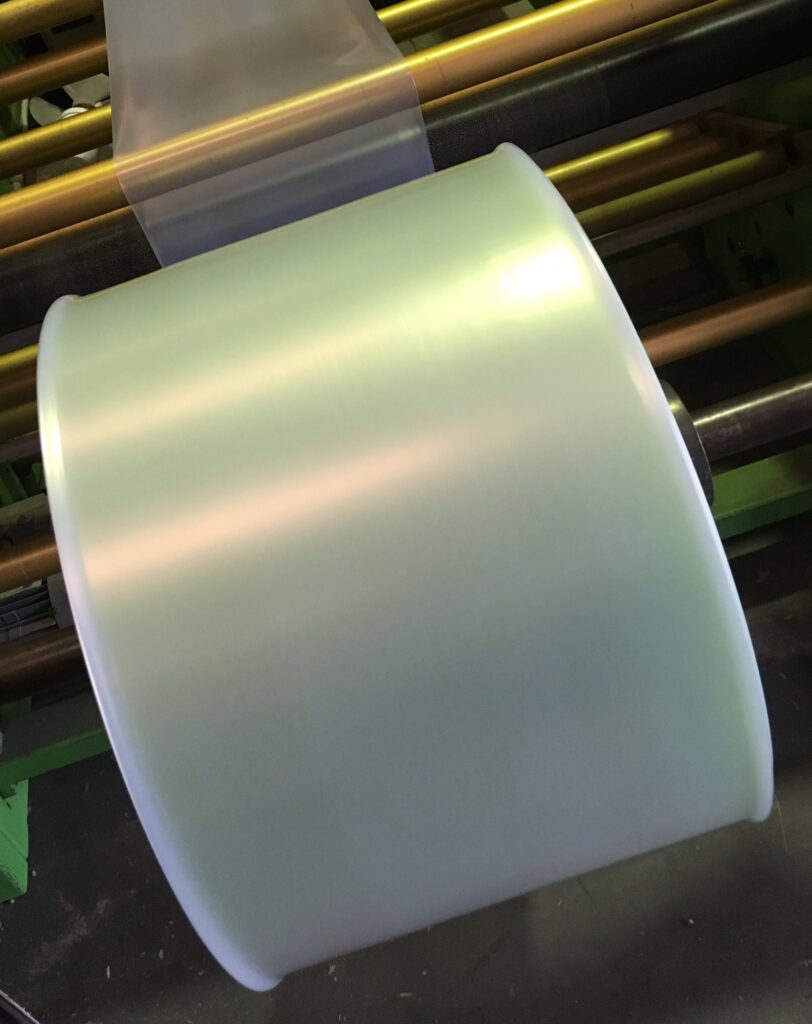

Polyethylene tube, or simply polytube, is a continuous length of extruded film that has been wound onto a roll, created through the process known as blown film extrusion. Small pellets of low density polyethylene (LDPE) virgin food grade resin are fed through our extruder at varying speeds to determine the desired gauge of the polytube. If a heavier weight tube is required, medium density (MDPE) or high density (HDPE) can also be used.

At Meridian we specialise in manufacturing smaller sized tube, with the ability to create polytube starting from 50mm wide. Like all Meridian products, polytube can be customised with print and colour allowing you to clearly label your product and promote your business.

Polytube is a practical and economical way to package objects which vary in length but have the same width. Once the product has been inserted into the tube, simply cut it to length as required. Individual bags can then be heat sealed, stapled or taped at either one or both ends, creating high quality and affordable packaging for your product.

What is Polytube?

Polyethylene tube, or polytube is a continuous length of extruded film that is wound onto a roll. Small pellets of low density polyethylene (LDPE) virgin food grade resin are fed into our extruder to create polytube through the process known as “blown film extrusion”. For heavier weight polyethylene tube products medium density (MDPE) or high density (HDPE) can be used.

We specialise in manufacturing smaller sized tube and can custom make polytube anywhere from 50mm wide upward and can print or colour to promote your business or product. Note that we can only print on 100mm or wider.

What is Polytube used for?

Wrapping

Packaging

Tree Guards

Mining Geological Samples

Protective Dust Covers

(Single Wound Sheet)

Types of Polytube

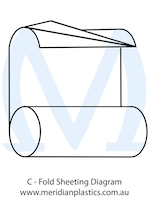

C-Fold Sheeting Diagram

Single Wound Sheeting Diagram

Double Wound Sheeting Diagram

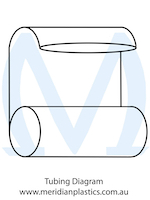

Tubing Diagram

Gusseted Tubing Diagram

Poly Tube Manufacturing Process

Many of our customers choose to use polytube to package their individual products. The first process of what we manufacture here at Meridian, polytube is created by blowing a bubble of plastic to form a tube. This process is known as blown film extrusion. Once the bubble is blown to its desired width, the gauge is then determined by the speed in which the nip rollers extrude the film from the machine. If a thick poly tube is required, the nip rollers will pull the film very slowly through the machine to increase thickness. To create a thinner gauge plastic, the speed of the nip rollers will be increased.

Frequently Asked Questions

What different colours can you produce?

Can you print on the plastic?

Is your plastic suitable for food packaging?

Can you recycle my unwanted plastic?

Is your plastic biodegradable?

Is your plastic recyclable?

Do you keep plastic bags and rolls of polytube in stock?

Do you have a price list or catalogue?

Do you make the product here in Australia?

What type of plastic products do you manufacture?

All of Meridian’s products are proudly made in Australia. We are Australian-owned and operated and therefore, can guarantee a fast and reliable turn-over.

Why Meridian?

With 35 years of industry experience, Meridian are the trusted experts when it comes to high quality and affordable custom packaging solutions. We are passionate about consistently delivering excellent service and high quality products at a fair and affordable price. As a local Australian business, we offer a fast turnaround so that our clients’ businesses can thrive.

Martin has spent the past three decades working exclusively in the plastics manufacturing industry and has dedicated his entire career to mastering the art of manufacturing quality plastic packaging products. Involved in every step of the process, Martin’s attention to detail alongside his passion, dedication and expertise prove to be an invaluable resource when it comes to customising packaging for your business.